Increased Reliability Dust Control Valves

Request full data and installation information.

The VXF2 series are manufactured by SMC, worldwide leaders in pneumatic technology.

- Modified solenoid armature design for increased reliability and less downtime.

- AC coils with built-in rectifier for greater reliability and quieter operation.

- Reduced noise operation for quieter installations.

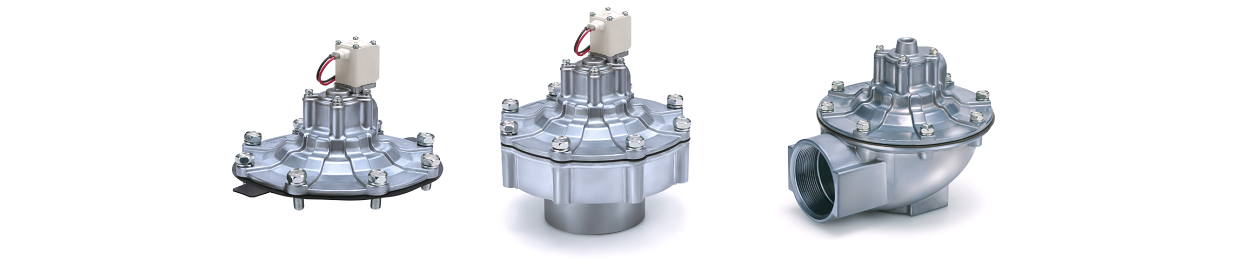

- Four body styles to allow installer to choose the best one for each installations.

- Flange type mounting for better cleaning than conventional valves.

- Flange body mounting type maximises cleaning performance and eliminates need for customer to form valve seat - faster installation and greater reliability.

- Multi valve controller

SMC produce both solenoid and air operated 2-port valves using in filter bag dusting applications, the VXF2 (solenoid type) and VXFA2 (air operated) valves are available with a range of orifice diameters from 20 to 100 mm .

SMC have recently introduced new high temperature versions rated for use on air at up to 100ºC.

Designed to offer enhanced durability in service these valves incorporate armature designs and full-wave rectified AC coils. The valve construction has been designed to reduce impact noise, including the use of a rubber buffer. These valves can also be specified with a silencer to reduce the noise of exhaust pilot air.

To allow installers to use a single valve range across the widest diversity installation types and sizes four styles of valve body are available:

- Direct piping with 3/4" to 4" G(BSP threaded bodies.

- Flange type with orifice from 65" 100mm

Two styles of flange body type both with factory produced 80mm orifice:

- Flange body I type flange mounting

- Flange body II type through hole mounting

SMC also offers two versions of the VXFC a dedicated multi-channel dust collector valve controller, the two versions offer 6 or 10 channel and can be cascaded together to control large numbers of valves. A switchable feature of the VXFC is the use of dual pulse feature which gives improved bag filter dusting efficiency.

Applications

Available with a wide range of port sizes from ¾" to 4" to accommodate the large bore market and industries such as iron and steel. With direct and flange piping, the VXF Series can be used in any system or industrial plant of any scale. Eg.

- Abrasive Blasting and Shot Blast

- Cement and Minerals

- Chemicals and Plastics

- Food Processing

- Foundry

- Glass

- Grain, Agriculture and Feed

- Laser Cutting

- Metalworking

- Mining and Mineral Products

- Pharmaceutical

- Plasma Cutting

- Thermal Spray

- Weld Fume

- Woodworking

A Supplier You Can Trust

With over 30 year's experience in the supply of solenoid valves and other fluid control products Beta Valve Systems can supply products from some of Europe's leading component manufacturers to meet your requirements in the areas solenoid valves, water meters, water filtration and pipe fittings.

Since 1991 we have produced our own range of solenoid valves which have been used in applications such as drinks vending industry, gas analysers, floor washers and hydroponics.

We place our customers at the centre of everything we do and strive to provide the highest quality products and service. We offer full technical support, from providing product datasheets straight from our website, to expert technical advice by email, phone or personal visit. Close ties with the manufacturers gives us direct access to our suppliers technical staff too.

To support your development or production requirements we can ship most ex-stock orders the same day from our extensive UK stocks. We also provide logistical support by holding buffer stock against call-offs and scheduled orders.

Request Call Back to Discuss

More about us