Coaxial Valves for High Reliability and Faster Operation with Maximum Flow Rate

Compared with conventional valves coaxial (or coax valves) use significantly fewer components leading to robust, highly reliable designs. At the same time the simplified more linear flow path through a coaxial valve gives superior flow rates when compared to conventional solenoid valves. In coaxial solenoid valves the integration of the solenoid coil into the valve body makes for a more efficient magnetic design giving the valve the ability to operate at a higher differential pressure operation and with reduced power consumption.

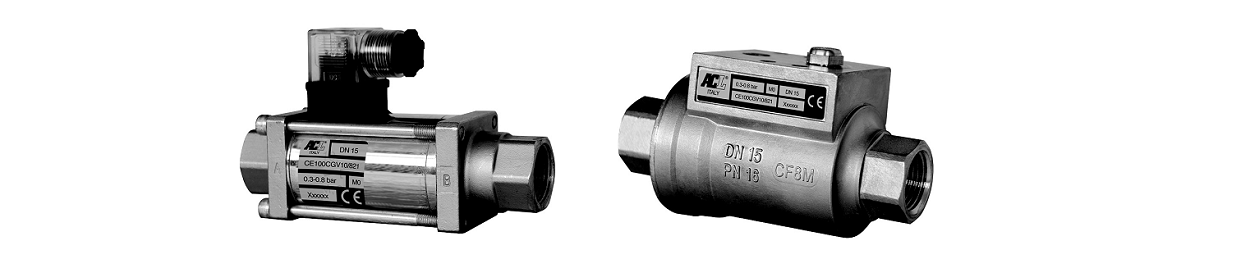

The CE100 and CP100 series are manufactured by ACL srl - One of Europe's leading manufacturers of solenoid valves. ACL’s valves are used worldwide in a variety of industrial sectors: water treatment, electrical appliances, industrial process, medical equipment, automotive, food, pneumatic and many others.

- Fewer components leading to a more dependable valve.

- Simplified flow path gives better flow rates.

- More efficient magnetic circuit gives faster operating times, higher maximum operating pressure and reduced power consumption.

- Stainless steel construction with FPM or EPDM seals maximises fluid compatibility.

Request Coaxial valves brochure with data sheet information.

ACL produce two ranges of coaxial valves: the CP100 series is pneumatically actuated and the second the CE100 series electrically driven.

The operating principle of these valves is very simple. The valve’s’ moving element has the main seal mounted on one end; when unpowered (or in the absence of a pneumatic signal) the valve’s orifice is closed by the main seal which is held in place by the return spring. When the valve is switched on (either pneumatically or electrically) the mobile element moves, compressing the return spring and opening the fluid flow path through the orifice to the application.

The inlet connection and the outlet connection are aligned on the same axis which simplifies installation on a pipe run.

These valves from ACL feature all stainless steel construction with FPM seal for maximum fluid compatibility, optional EPDM seals allow use with hot water or steam.

The coaxial solenoid valve of the CE100 series are available in sizes 3/8” to 1”, the solenoid coil is integrated into the valve body. This optimises the coil position for maximum magnetic efficiency, this permits operation up to 40 bar and significantly reduces power consumption compared with the traditional solenoid valve design. Increased magnetic efficiency also yields faster operating times and permits a larger valve orifice size for a given pressure and coil power consumption.

Available in sizes 3/8” to 2” the coaxial valves of the CP100 series are controlled by a pneumatic signal. They have excellent characteristics of reliability and robustness and good operating time. With a very simple robust design the CP100 offers high reliability in demanding applications. Versions with a pilot solenoid valve mounted on the body are available to special order.

Uses for Coaxial Valves

Typical Applications

With high flow rates and robust designs the CE100 and CP 100 coax valves are suitable for a number of demanding applications including:

- Packaging machinery

- Bottle filling machinery

- Process equipment

- PET blowing machines

- Powder transport

A Supplier You Can Trust

With over 35 years' experience in the supply of solenoid valves and other fluid control products Beta Valve Systems can supply products from some of Europe's leading component manufacturers to meet your requirements in the areas solenoid valves, water meters, water filtration and pipe fittings.Since 1991 we have produced our own range of solenoid valves which have been used in applications such as drinks vending industry, gas analysers, floor washers and hydroponics.

We place our customers at the centre of everything we do and strive to provide the highest quality products and service. We offer full technical support, from providing product data sheets straight from our website, to expert technical advice by email, phone or personal visit. Close ties with the manufacturers gives us direct access to our suppliers technical staff too.

To support your development or production requirements we can ship most ex-stock orders the same day from our extensive UK stocks. We also provide logistical support by holding buffer stock against call-offs and scheduled orders.

More about us